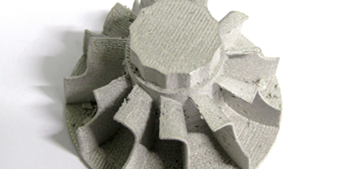

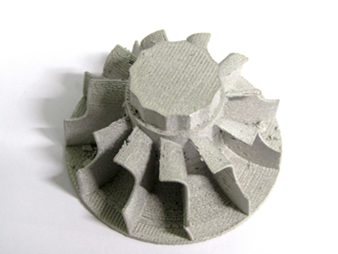

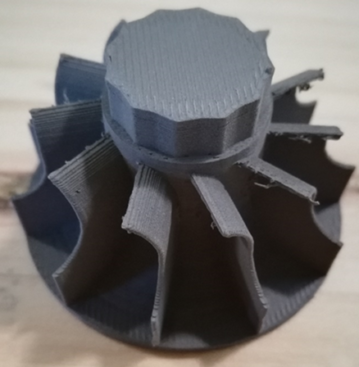

Printing 316L metal turbines with Ultrafuse® filament and the RAISE 3D Pro 2:

Thanks to the PEPS project, we were able to print a turbine in 316L with the RAISE 3D Pro 2 and the 316L Ultrafuse® filament from BASF. Compared to different printing technologies (powder bed with laser beam (here SLM Solution®), powder bed with printing cartridge (here Exone® and Digital Metal®), granule printing (here AIM 3D® and 3D FIGO®) and filament printing (here Markforge®), the characterisation results of this new turbine (Surface rougnhness, Chemical analysis, Material health, Density, etc…) have nothing to be ashamed of compared to the other technical solutions. Contact us if you wish to obtain this new study. It is available on request by completing our industry questionnaire on our website!

Enjoy reading!