As part of the PEPS project, we attended the annual powder metallurgy congress (EPMA 2020) of the 5th, 6th and 7th of octobre and it was a virtual congress.

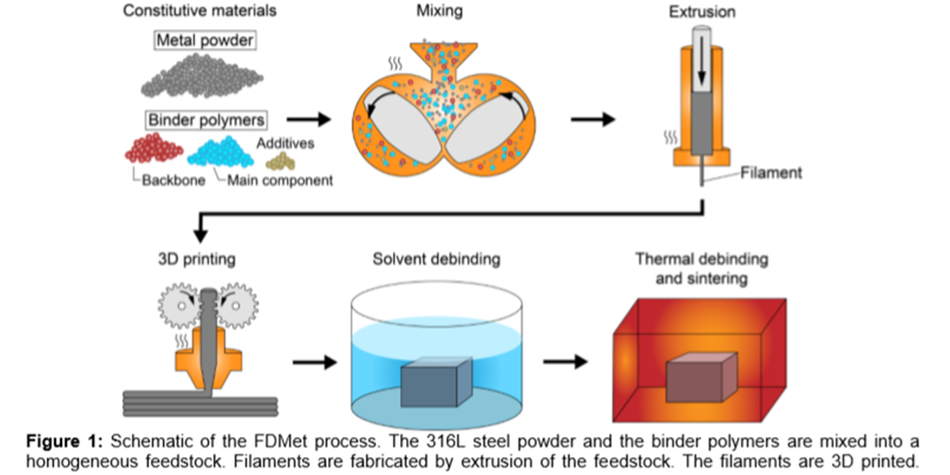

In this congress different topics were discussed, in particular the PIM-Like process and the development of feedstocks (Metal powder + Polymer binder).

Indeed, the development of feedstocks is a crucial step in the PIM-LIKE process. The optimal solids loading is the first parameter to be defined because it ensures a good balance between fluidity, flexibility and stiffness in the innovative feedstock (filament or powder) ; and it must be between 50% vol and 60% vol.

- Naranjo [1] has shown that the binder is a very important component in the development of feedstock which is made up of a combination of elastomers, backbone and additives; and which it has an influence on the properties of the final parts. In addition, M. Wagner [2] confirmed this, by using two different binders in order to show their influences on the viscosity and stiffness of the feedstock.

Finally, a rheological study for the feedstock is essential to optimize the parameters of 3D printing (viscosity, shear rate, etc.).

Do not hesitate to contact us to have more information on PIM-like process and on feedstocks.

[1] Marius A. Wagner, Feedstock development for fused deposition of 316L stainless steel and characterization of final materials properties.

[2] Juan Alfonso Naranjo, Fused Filament Fabrication of PIM-like M2 High Speed Steel parts: production and characterization.