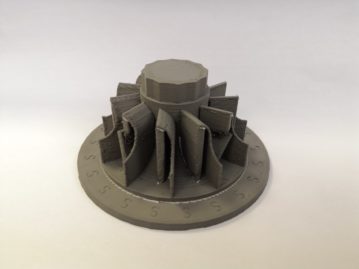

Within the framework of the PEPS project, we wanted to compare different additive manufacturing technologies known as “PIM like” available on the market to print metal turbines. The technologies chosen for this comparative study are the SLM technology (Powder Bed with Laser Beam), the Binder Jetting technology (Powder Bed with polyme’s droplets), the FFF technology (Fused Filament Fabrication: Coil of metal-filled filaments) and the FFD technology (Fused Feedstock Deposition: Metal-filled pellet extruder set up on an FFF type printer). These last 3 technologies require the post-treatments of debinding and sintering to obtain the metal parts.

3 turbines were printed in 316L, 1 in 17-4PH, 1 in TA6V and 1 in aluminium. This 60-page study compares the dimensional aspects, roughness, chemical analysis, internal defects by radiography/tomography and material health (porosity, microstructure and grain size) of these turbines.

You can receive the complete study by filling out our online questionnaire at https://www.peps-interreg.eu/