What’s new in 3D printing of TA6V titanium alloy?

Titanium is a light, non-magnetic, corrosion resistant, biocompatible material used in many fields, mainly aeronautics, aerospace, dental and medical.

In 3D printing, the titanium alloy used is TA6V, a titanium alloy containing 6% aluminium and 4% vanadium, which increases the mechanical properties compared to pure titanium.

The parts produced in titanium are currently printed by powder bed printing:

- Either by laser fusion with SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering) technologies.

- Or by electron beam melting, called EBM for Electron Beam Melting, a more expensive technology.

- Or by binder to generate a green part that will have to be densified, this is the patented Digital Metal® technology, which is on the borderline between powder bed printing and Metal Injection Molding, MIM, using sintering as a post-treatment to densify the parts after printing.

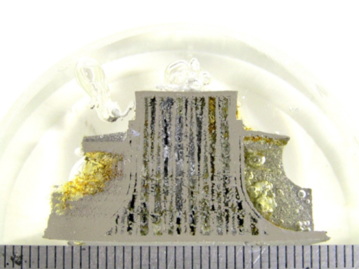

But did you know that it is possible to produce printed titanium parts using an FDM (fused deposition modelling) printer that uses a pellet extruder rather than filaments? Less expensive, this process will make it possible to print so-called green parts, polymer composites and metal powders from granules produced by MIM technology. Then, the printing will have to be followed by a debinding step to remove the polymers and a sintering step to densify the part, it is the MIM like process. We have already written articles on this subject, which is a focus of the Interreg PEPS project, as we are working to develop a feedstock formulation better suited to this type of printing.

There are many machine suppliers in Europe, Tumaker® in Spain, Pollen® and EPEIRE 3D® in France, 3D FIGO® and AIM 3D® in Germany, etc., which offer 3D printing machines using extruders for pellets, also known as feedstocks, in TA6V, which already exist for MIM technology, in particular the POLYMIM TA6V® or the Catamold® Ti using pure titanium.

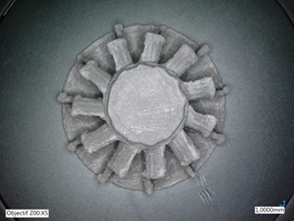

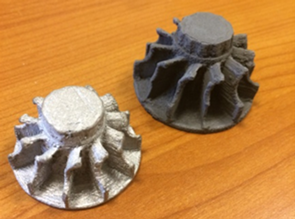

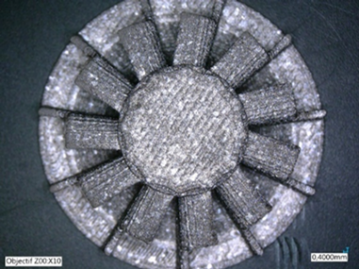

The PEPS consortium has tested and compared for you the 3D FIGO and EPEIRE 3D solutions with the TA6V feedstock from POLYMIM®. The parts are presented and characterised in the third version of the “comparative study for a given metal part (turbine) printed with different PIM-like processes available on the market”. You will find data on surface aspects, material health of the printed parts, densities obtained, chemical analysis of the printed grades, etc… This report is available on request at the following e-mail address: info@peps-interreg.eu.

Do not hesitate to contact us for more information!