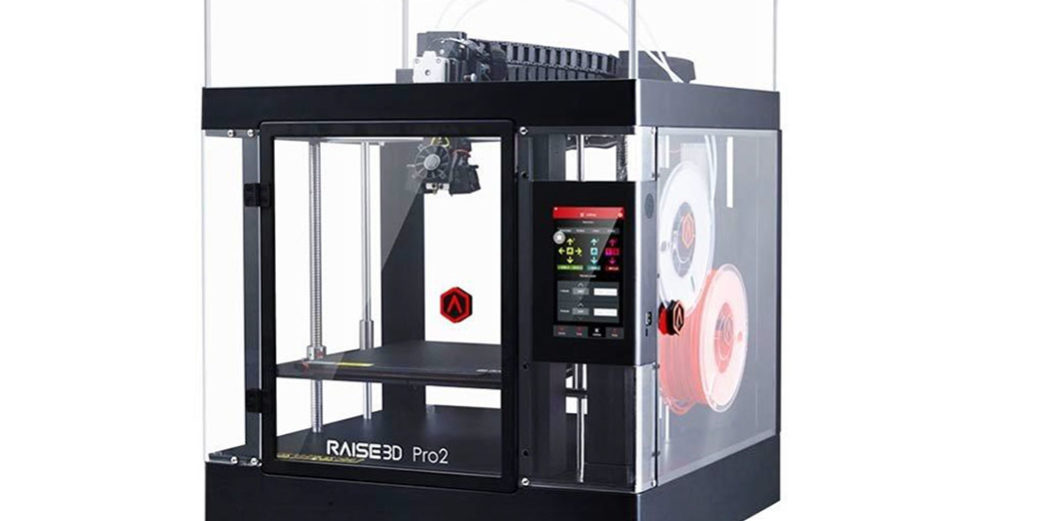

Thanks to the PEPS project, the CRITT-MDTS got a new 3D printer, Raise 3D Pro2. That printer have a lot of advantages like an enclose chamber in order to control the temperature, two nozzles to print with a material support and a large printing volume of 305x305x300mm.

The CRITT-MDTS began the printing with the 316L of BASF which commercial name is « ultrafuse® ». This filament is composed by 88%w of metallic particles and has a polymer sleeve.

The printing is quite easy, thanks to theoretical parameters communicated by BASF which are good. The R&D needed one day to find good parameters which can change depending on the printer. Larger disadvantages are the porosity and the warping during the printing.

However, the results are promising, with a green part density of 98% compared to a theoretical value.

Coming soon, printing of tensile dog bones, debinding and sintering of green samples.